Structure

Function

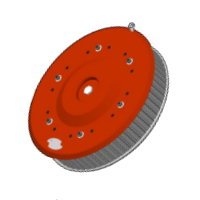

ZiInCheol - Crankcase explosion relief valve

References

| Competition | |

|---|---|

| Separation | Dual Passage Structures enables excellent Flame disconnections & improved Cooling effects |

| Structure | Lamellar structures enables excellent Block, Stability and Safety Excellent durability to explosive pressure |

| Resistance | The protrusion of the Lamellar is inserted at the groove of the Seat to stop any movement even during explosion |

| Standard | Inner and outer lamella design applied for all ranges of Crankcase Relief Valves products |

| Strength | Strengthening the Disc stiffness and the Disc structure enabled Open Pressure to maintain even after a secondary explosion |

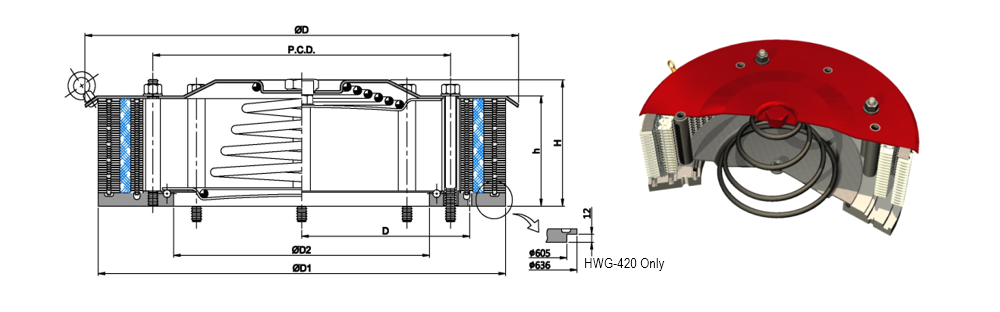

| Model | Outflow Area(㎠) |

ØD1(mm) | ØD2(mm) | ØD(mm) | h(mm) | H(mm) | D(mm) | Mounting Bolt |

P.C.D.(mm) | Approx. weight(kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| HWG-735 | 3904 | 969 | 705 | 1008 | 288 | 318 | 425 | 12-M16 | 795 | 245 |

| HWG-645 | 2990 | 871 | 617 | 910 | 250 | 280 | 378 | 12-M16 | 700 | 190 |

| HWG-565 | 2299 | 784 | 541 | 823 | 222.5 | 252.5 | 335 | 12-M16 | 615 | 153 |

| HWG-480 | 1662 | 699 | 460 | 738 | 187 | 215 | 287 | 8-M16 | 530 | 117 |

| HWG-420 | 1257 | 636(605) | 400 | 678 | 167 | 191 | 251 | 8-M16 | 465 | 93 |

| HWG-345 | 830 | 556 | 325 | 595 | 147 | 164 | 214 | 6-M16 | 390 | 72 |

| HWG-320 | 731 | 510(605) | 305 | 547 | 137 | 154 | 197.5 | 6-M12 | 355 | 59 |

| HWG-266 | 499 | 418 | 252 | 435 | 101.3 | 109.9 | 170 | 6-M12 | 302 | 26 |

| HWG-224 | 346 | 371 | 210 | 392 | 89.3 | 96.6 | 142 | 6-M12 | 255 | 22 |

| HWG-204 | 284 | 351 | 190 | 367 | 79.3 | 86.6 | 132.5 | 6-M12 | 235 | 20 |

| HWG-173 | 201 | 319 | 160 | 335 | 70.8 | 77.8 | - | 6-M10 | 203 | 14 |

| HWG-162 | 177 | 306 | 150 | 322 | 64.3 | 71.3 | - | 6-M10 | 190.5 | 13 |

| HWG-122 | 95 | 262 | 110 | 278 | 55.3 | 62.6 | - | 6-M8 | 150 | 9 |

| HWG-098 | 59 | 237 | 87 | 250 | 44.3 | 51.6 | - | 4-M8 | 122 | 7 |

Eye bolts from HWG-345

(H) Means Hinged type explosion relief valve