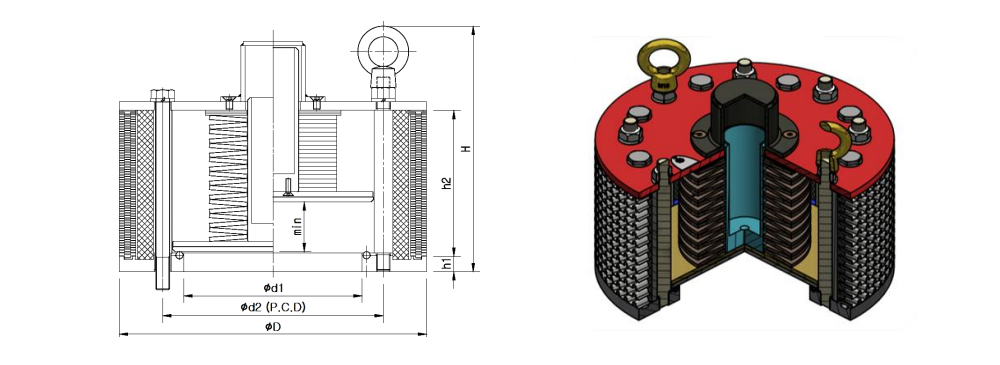

Structure

Function

ZRI - explosion Relief valve for air Intake

References

| Competition | |

|---|---|

| Separation | Flame arrester which were optimally combined with lamellar and wire mesh These enable excellent flame disconnections & improved cooling effect |

| Structure | Lamellar structures enable excellent block, stability and safety Excellent durability to explosive pressure in high pressure environment |

| Resistance | The protrusion of the lamellar is inserted at the groove of the Seat to stop any movement even during explosion |

| Standard | Lamella and wire mesh combination design applied for all ranges of ZRI relief valves products |

| Strength | Strengthening the dual discs structure enabled opening pressure to maintain even after a secondary explosion |

| Model(ZRI) | Outflow Area(㎠) |

ØD1(mm) | ØD2(mm) | ØD(mm) | min(mm) | h1(mm) | h2(mm) | H(mm) | Mounting Bolt |

P.C.D.(mm) | weight(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ZRI-98 | 59 | 87 | 122 | 199 | 24 | 15 | 112 | 169 | 4-M10 | 122 | 12 |

| ZRI-122 | 95 | 110 | 150 | 227 | 30 | 15 | 121 | 180 | 6-M10 | 150 | 17 |

| ZRI-173 | 204 | 160 | 203 | 280 | 43 | 18 | 160 | 219 | 8-M10 | 203 | 32 |

| ZRI-224 | 346 | 210 | 260 | 341 | 56 | 18 | 200 | 289 | 8-M16 | 260 | 49 |

| ZRI-266 | 499 | 252 | 302 | 383 | 67 | 18 | 213 | 302 | 8-M16 | 302 | 69 |

ZRI-A valve (for high pressure) is the most important factor in developing a valve to open and close at a pressure of 5.8 to 6.3 bar.