Structure

Function

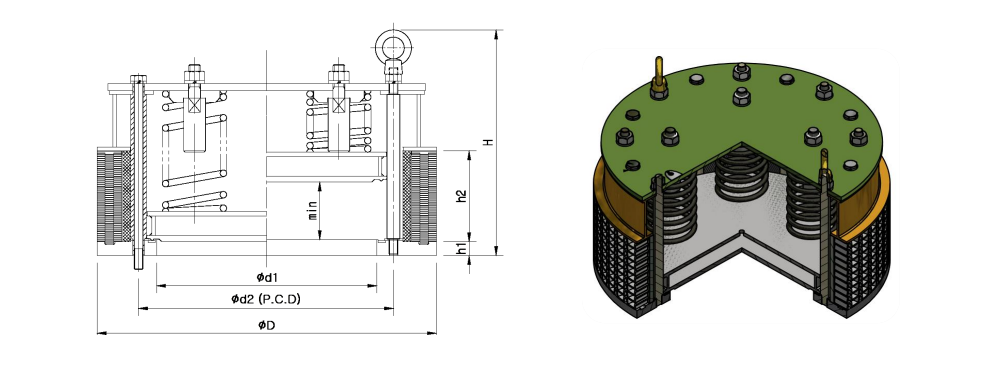

ZRE - explosion Relief valve for Exhaust system

References

| Competition | |

|---|---|

| Separation | Flame arrester which were optimally combined with lamellar and wire mesh These enable excellent flame disconnections & improved cooling effect |

| Structure | Stainless lamellar structures enable excellent block, stability and safety Excellent durability to explosive pressure and in high temperature environment |

| Resistance | The protrusion of the Lamellar is inserted at the groove of the Seat to stop any movement even during explosion |

| Standard | Lamella and wire mesh combination design applied for all ranges of ZRE relief valves products |

| Strength | trengthening the dual disc structure enabled open pressure to maintain even after a secondary explosion |

| Model(ZRE) | Outflow Area(㎠) |

ØD1(mm) | ØD2(mm) | ØD(mm) | min(mm) | h1(mm) | h2(mm) | H(mm) | Mounting Bolt |

P.C.D.(mm) | weight(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ZRE-320 | 731 | 305 | 355 | 470 | 81 | 19 | 126 | 312 | 6-M12 | 355 | 63 |

| ZRE-420 | 1257 | 400 | 465 | 585 | 106 | 19 | 166 | 383 | 8-M16 | 465 | 116 |

| ZRE-565 | 2299 | 541 | 615 | 735 | 144 | 19 | 233 | 476 | 12-M16 | 615 | 210 |

| ZRE-735 | 3904 | 705 | 795 | 915 | 187 | 19 | 310 | 619 | 12-M16 | 795 | 355 |

The most important factors are the application of sealing that maintains air tightness even (at high temperatures) above 460°C and the development of a material that can withstand high temperatures.